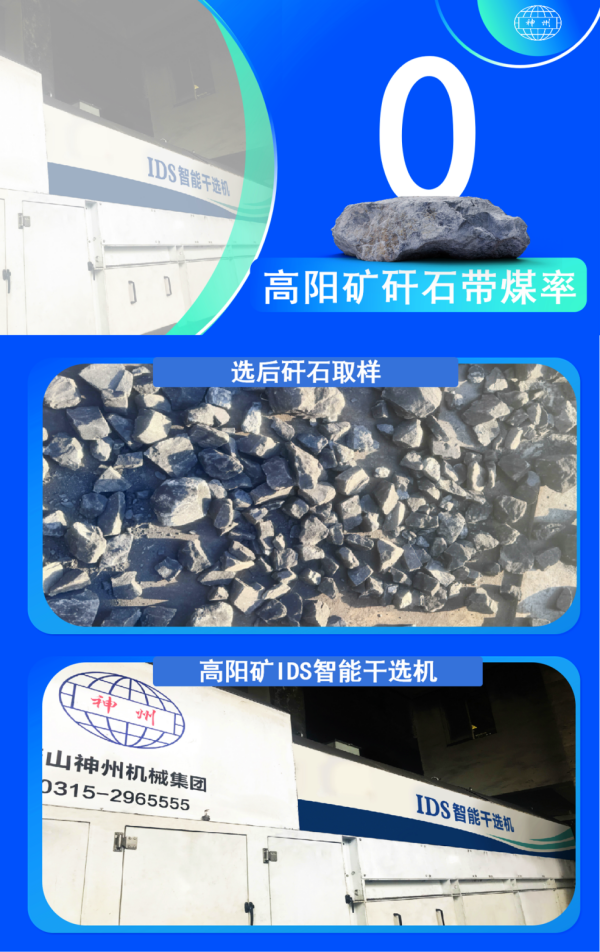

Big News!Recently, the Shenzhou IDS Intelligent Dry Separator at the Gaoyang Coal Mine, part of the Shanxi Coking Coal Group, achieved another legendary milestone with its “excellent performance.” Following preparation, the sampling rate of reject containing coal reached an impressive “0,” setting a new benchmark for preparation accuracy in the field of intelligent dry preparation technology.

Project Overview

Gaoyang Coal Mine, a subsidiary of Shanxi Fenxi Mining (Group) Co., Ltd., previously utilized vibro-assisted jigging to discharge 200-50mm large coal. However, due to outdated discharge processes, the reject contained a coal-carrying rate of 5-8%. In April 2023, Gaoyang Coal Mine upgraded its operations by purchasing two IDS-2000A intelligent dry separators from Tangshan Shenzhou Manufacturing Group, replacing the original vibro-assisted jigging system. After implementation, the hourly separation capacity exceeded 400 tons.

Separation Performance

Coal rate in reject: Averaged below 0.5%, with the lowest reaching 0%.

Efficiency: More than 4,000 tons of reject are discharged daily, reducing clean coal losses by 200-300 tons.

Economic Impact: The operation of Shenzhou's intelligent dry separation system has significantly lowered costs, delivering substantial economic benefits to the coal mine.

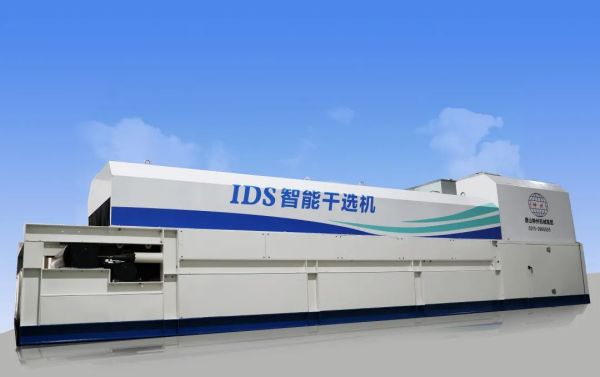

Intelligent Dry Separator

The Shenzhou intelligent dry separator is designed for coal preparation within particle size ranges of 25-100mm and 50-300mm. It features intelligent reject identification, automated air-blowing, and a fully automated preparation process, eliminating the need for manual labor. Key advantages include high preparation accuracy, a high degree of intelligence, and a simplified process flow. These benefits make it invaluable for applications such as:

Pre-discharge of reject from coking coal,

Thermal coal quality improvement,

Integration of underground "picking-preparation-charging" processes,

Coal disposal, and

Recycling of dirty mixed coal.

Additionally, this model has been granted exemptions for radioactive isotopes and radiation devices, ensuring compliance with safety standards.

Since its inception in 2008, Shenzhou's intelligent dry preparation technology has been successfully applied across major coal-producing provinces and regions, including Shanxi, Inner Mongolia, Heilongjiang, Ningxia, Guizhou, Xinjiang, and Hebei. Measured application data shows an average reject coal rate of less than 1% and a reject discharge rate exceeding 95%.

Reject with coal is "0"! Shanxi Coking Coal Group's IDS intelligent reject separation index refresh industry record!